What is AQL Acceptable Quality Level? ( Free AQL Table Download)

What is AQL Acceptable Quality Level?

The Acceptable Quality Level (AQL) originated in the field of quality control and was developed as a standard to measure and maintain the quality of products.It has been widely used in manufacturing and production industries to ensure that products meet certain quality standards before they are released to the market.

AQL refers to the maximum number of defective units in a sample size that can be considered acceptable during a product inspection. The purpose of AQL is to provide a benchmark for quality control, allowing manufacturers to determine the acceptable quality level for their products.

AQL is not an absolute measure of quality, but rather a tool for managing risk and ensuring that a product meets certain predetermined standards. AQL is typically expressed as a percentage, such as 1%, 2.5%, or 4%, indicating the maximum allowable percentage of defective units within a sample.

Importance of AQL in quality control standards

The Acceptable Quality Limit (AQL) plays a crucial role in quality control standards by providing a systematic approach to inspecting and evaluating product quality. It helps establish quality limits, determine appropriate sample sizes for random sampling inspection, and define clear acceptance criteria for products.

AQL also ensures that products consistently meet predetermined quality standards, preventing the release of defective or substandard items into the market.

Understanding AQL Sampling Levels

Acceptable Quality Level (AQL) is a cornerstone of quality control, establishing the maximum percentage of defective items allowed in a product lot or batch size. However, AQL doesn’t operate independently; it’s inherently linked to inspection levels, which determine the balancing point between quality assurance and the intensity of your inspection process. Now, let’s dive into the different AQL inspection levels, their significance, and how to choose the right ones for your specific needs.

Special Inspection Levels(Table 1)

Special Inspection Levels are designed for specific scenarios and are divided into four categories:

- S-1: This level is used for critical defects, where even a single defect is unacceptable. It involves the largest sample size and the most strict acceptance criteria among all levels.

- S-2: This level is for major defects that could significantly impair the product’s functionality or safety. It involves a larger sample size than general inspection levels but a smaller one than S-1.

- S-3: This level is for major defects that could affect the product’s appearance or usability but are not as critical as S-2 defects. It involves a smaller sample size than S-2.

- S-4: This level is for minor defects that have little to no impact on the product’s overall performance or safety. It involves the smallest sample size among special inspection levels.

General Inspection Levels (Table 1)

General Inspection Levels are the most common in AQL and are divided into three categories:

- GI- General Inspection Level I (Reduced Inspection): This level is typically used when a supplier has a proven track record of consistently delivering high quality products. It involves smaller sample sizes and is a cost effective option for maintaining ongoing quality assurance. However, it carries a slightly higher risk of accepting a lot with defects compared to other levels.

- G-II- General Inspection Level II (Normal Inspection): The default level for most AQL inspections, Level II provides a moderate level of inspection. It is suitable for most products and situations where there is no prior quality history with the supplier or when the risk of defects is moderate.

- G-III- General Inspection Level III (Tightened Inspection): This level is employed when there is a history of quality issues with a supplier or product. It requires larger sample sizes and stricter acceptance criteria, making it less likely to accept a lot with defects. However, it also increases inspection costs and may lead to rejecting good lots more frequently.

AQL Example:

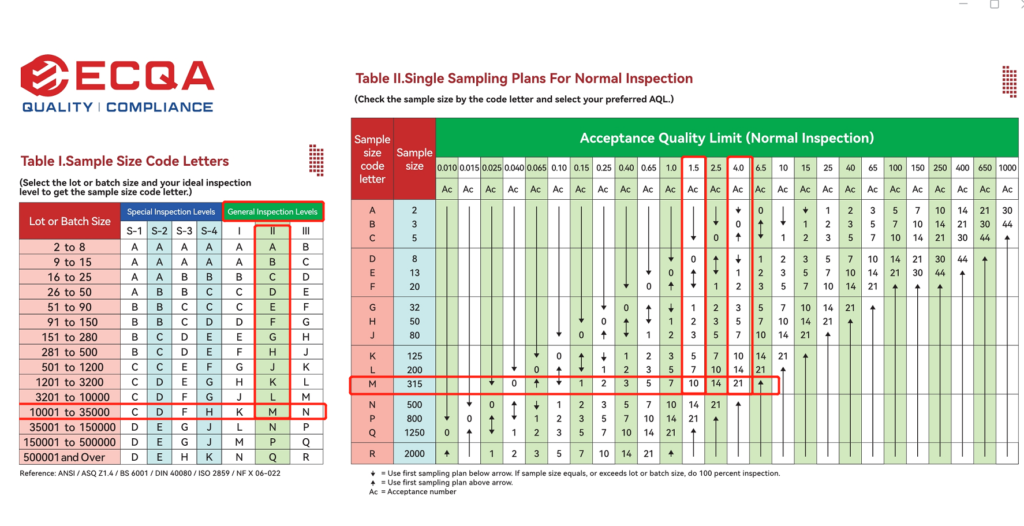

Download Free HD AQL Table

A company producing children’s toys might implement an AQL inspection plan as follows:

- Batch Size: 20,000 Toys

- Inspection Level: G-II (General inspection Level)

- Acceptable Quality Limits (AQL):

- Critical Defects: 0% (Zero Tolerance – No critical defects allowed)

- Major Defects: 1.5% (maximum allowable percentage of defective units within a sample)

- Minor Defects: 4.0% (maximum allowable percentage of defective units within a sample)

Based on this AQL plan (Ref: AQL tables based on ANSI/ASQ Standard Zq1.4):

- Sample Size: 315 toys (determined using AQL tables and sample size code letters)

- Acceptance Criteria:

- Critical Defects: 0 (zero tolerance)

- Major Defects: 10 (maximum allowable number in the sample)

- Minor Defects: 21 (maximum allowable number in the sample)

The company will randomly select 315 toys from the batch of 20,000. If the number of critical, major, or minor types of defects found in the sample exceeds the accepted defects outlined in the AQL standard, the entire batch will be rejected. This ensures that the toys meet the required quality standards before they are shipped to customers. You can also use an AQL calculator to help you determine the right sample size code letters for your inspection.

How to Choose the Right Sampling Level

Choosing the right AQL (Acceptable Quality Limit) level is a crucial step in ensuring product quality while balancing the need for efficiency and cost effectiveness. Here’s a guide to help you make an informed decision:

1. Understand AQL Levels and Their Impact

- Recall that AQL levels represent the maximum acceptable percentage of defective units in a lot.

- Lower AQL indicates a stricter quality standard with lower tolerance for defects.

- Higher AQL allows for a higher percentage of defects.

2. Factors to Consider When Choosing Your AQL

- Product Criticality

Is your product safety critical (e.g., medical devices, automotive parts) or used in a high risk environment? If so, a lower AQL is recommended to minimize the risk of defects. - Product Complexity

For products with multiple components or complex functions, a stricter AQL may be necessary to ensure all aspects meet quality standards. - Supplier History

If you have a new or unreliable supplier, a stricter AQL can mitigate risks. A well-established supplier with a history of consistent quality might allow for a more lenient AQL. - Risk Tolerance

How much risk are you willing to accept for receiving defective products? If your risk tolerance is low, choose a lower AQL. - Inspection Costs

Higher AQLs generally require smaller sample sizes and thus less inspection time and cost. If budget is a constraint, you may need to balance quality requirements with affordability.

3. Refer to Industry Standards and Regulations

Many industries have established AQL recommendations for specific product types, which can serve as a helpful starting point for your decision making process. Additionally, be aware of any regulatory requirements that may dictate specific AQL levels within your industry.

4. Consult with Third Party Inspection Experts

If you are unsure about the most suitable AQL level for your specific situation, don’t hesitate to consult with experts. Quality assurance professionals or consultants have the knowledge and experience to assess your risk profile, product specifications, and industry requirements to recommend the most appropriate AQL level.

Furthermore, partnering with a third party inspection company can provide valuable insights into industry best practices and help you develop a tailored AQL plan that aligns with your quality goals and budget.

As a leading third-party inspection company, ECQA can guide you through the complexities of AQL selection and implementation. Our team of quality assurance experts will assess your unique needs and provide tailored solutions to ensure your products consistently meet or exceed quality standards. Contact ECQA today to learn more about our comprehensive quality control services and how we can help you achieve your quality goals.

Request Free Sample Report

Request Free Sample Report