During Production Inspection (DUPRO)

Service Overview

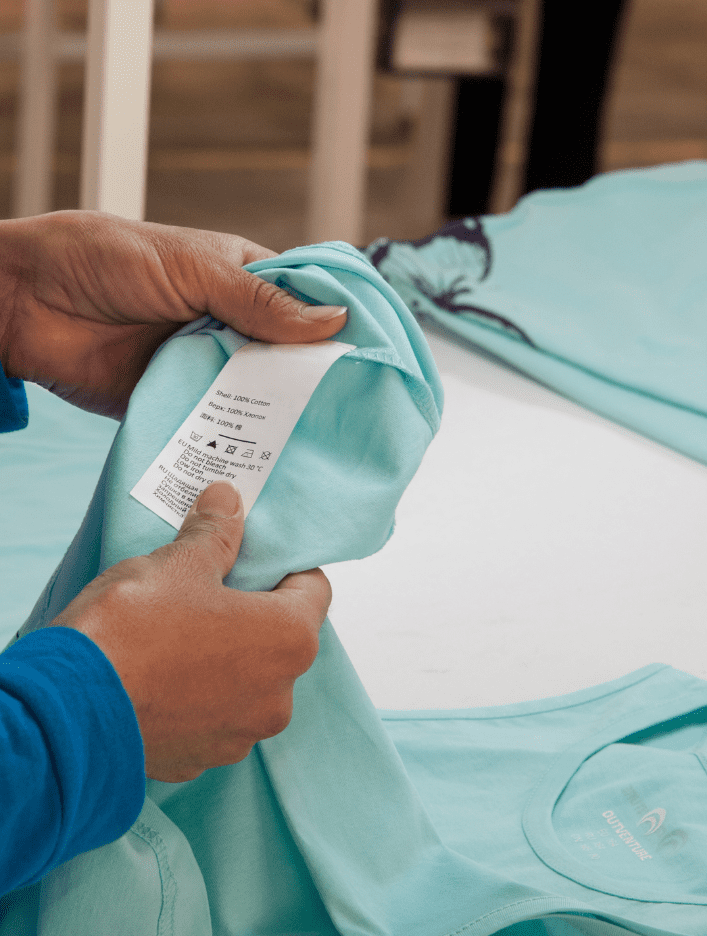

During Production Inspection (DUPRO) is a quality control process that involves actively inspecting components and partially finished products at various stages of the manufacturing process. This proactive approach allows for any issues or defects to be identified and addressed before the final product is completed.

DUPRO inspections help to ensure that quality standards are being met throughout the production process. By inspecting components and partially finished products as they move through different stages of manufacturing, manufacturers can prevent defects from accumulating and ultimately reduce the likelihood of producing faulty products.

DUPRO inspections also provide manufacturers with the opportunity to make any necessary adjustments or improvements to the production process in real-time, leading to a more efficient and effective manufacturing operation.

To ensure consistent quality throughout the manufacturing process, ECQA's quality control inspectors conduct on-site DUPRO inspections at a stage when between 10% and 80% of the finished goods are produced.

DUPRO inspections help to ensure that quality standards are being met throughout the production process. By inspecting components and partially finished products as they move through different stages of manufacturing, manufacturers can prevent defects from accumulating and ultimately reduce the likelihood of producing faulty products.

DUPRO inspections also provide manufacturers with the opportunity to make any necessary adjustments or improvements to the production process in real-time, leading to a more efficient and effective manufacturing operation.

To ensure consistent quality throughout the manufacturing process, ECQA's quality control inspectors conduct on-site DUPRO inspections at a stage when between 10% and 80% of the finished goods are produced.

Why Conduct During Production Inspection (DUPRO)?

During Production Inspection (DUPRO) is a critical quality control process that helps ensure the consistent production of high-quality products. DUPRO inspections go beyond raw material checks by examining components and semi-finished products throughout the manufacturing process.

By conducting inspections at various stages throughout the manufacturing process, companies can identify and address issues before they escalate, ultimately saving time, money, and resources. This proactive approach allows manufacturers to maintain tight control over their production, ensuring that each unit meets the necessary standards and specifications.

By conducting inspections at various stages throughout the manufacturing process, companies can identify and address issues before they escalate, ultimately saving time, money, and resources. This proactive approach allows manufacturers to maintain tight control over their production, ensuring that each unit meets the necessary standards and specifications.

The Benefits of During Production Inspection (DUPRO)

Conducting a During Production Inspection (DUPRO) is essential for ensuring the quality and compliance of products during the manufacturing process. This proactive approach offers several advantages:

- Improved Production Efficiency: DUPRO helps identify bottlenecks or production quality issues early on, ensuring a smoother and more efficient overall process.

- Ensured Product Quality: Consistent quality checks throughout production with DUPRO lead to final products that meet all required quality standards and product specifications. This translates to increased customer satisfaction and brand reputation.

- Save Costs: Early detection of issues minimizes the need for rework, scrap materials, and production delays, leading to significant cost savings in the long run.

- Enhanced Production Efficiency: By identifying bottlenecks and inefficiencies early, DUPRO allows you to optimize your production process for smoother operation and increased output.

How to Conduct a During Production Inspection (DUPRO)?

To conduct a During Production Inspection (DUPRO), companies can work with a third-party inspection service that specializes in quality control and production processes. a team of inspectors visiting the manufacturing facility at a mid-point in production (typically 10-80% complete). The inspectors will assess the products, materials, and production processes against agreed-upon specifications. This includes examining samples, evaluating production tools and components, and verifying adherence to the production schedule.

- Free consultation

Schedule your During Production Inspection (DUPRO) with ECQA and experience a stress-free, compliant, and quality-assured start to your production journey. Reach out to our team of experts who are ready to assist you every step of the way.

Email us Get a free quote

sales@ecqa.com

Have any Questions? Message us Today!

Book your Inspection

Don't let quality issues or compliance problems disrupt your business. Contact us today to schedule your first third-party inspection with ECQA.

Email Us

Request Free Sample Report

Request Free Sample Report