Physical and Mechanical Testing for Product Safety and Compliance

Physical and mechanical testing is the foundation of modern quality assurance for consumer products, industrial goods, and packaging materials. Every item that reaches the hands of consumers, whether it is a children’s toy, an electronic appliance, or a food contact container, must withstand real world use and comply with international safety regulations.

What is Physical and Mechanical Testing?

Physical testing measures the inherent properties of a material or product. These properties include dimensions, weight, density, hardness, abrasion resistance, colorfastness, and surface characteristics. Physical tests describe what a product is in measurable terms and confirm whether it conforms to defined specifications.

Mechanical testing evaluates how a product performs when subjected to applied forces. It examines strength, deformation, durability, fatigue resistance, and failure behavior. Mechanical tests determine how a product responds to real-world use, shipping conditions, or repeated stress.

Both test categories create a comprehensive profile of product safety, performance, and regulatory compliance.

Common Physical and Mechanical Test Methods

The following test groups represent the methods most frequently used across consumer goods, industrial parts, and packaging systems.

Durability Testing and Strength Evaluation

These tests determine whether a product can withstand regular use without breaking or deforming. Typical assessments include:

- Load-bearing tests for furniture

- Zipper cycle tests for garments

- Hinge endurance tests for appliances

- Fastener strength tests for hardware

- Fabric tensile and tear tests for textiles

Durability data supports long-term reliability evaluations and helps identify weak components before mass production.

Impact, Drop, and Fatigue Testing Methods

Impact and drop testing simulate accidental falls and rough handling during logistics or consumer use. Fatigue testing applies repeated stress cycles to evaluate long-term performance.

Examples include:

- Drop tests for electronics

- Impact tests for packaging and containers

- Fatigue bending tests for cables and flexible components

- Shock resistance tests for fragile goods

- These tests verify whether a product maintains integrity under transport and daily handling.

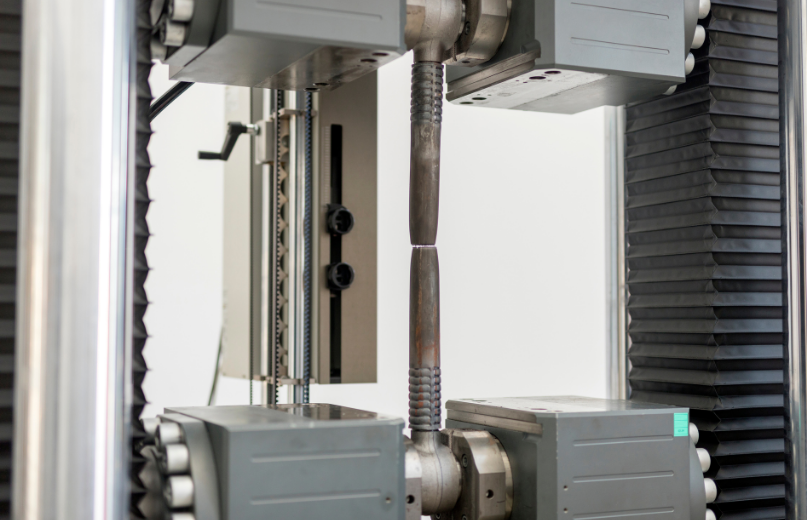

Tensile, Compression, and Bending Strength Tests

These tests measure resistance to applied forces.

- Tensile testing stretches a sample until failure to determine elongation and break strength

- Compression testing evaluates resistance to crushing

- Bending tests assess stiffness and flexibility

These methods are widely used for plastics, metals, packaging materials, construction components, and molded parts.

Sharp Edge, Sharp Point, and Small Parts Testing

Children’s products require specific mechanical safety evaluations under toy safety standards.

Common tests:

- Sharp edge test

- Sharp point test

- Small part cylinder test for choking hazards

- Torque and tension tests for components that may detach

Compliance with standards such as EN 71 and ASTM F963 is mandatory before toys enter global markets.

Packaging Integrity and Transport Simulation

Packaging must protect goods throughout the supply chain. Testing evaluates whether packaging materials can withstand compression, vibration, and impact.

Key assessments:

- Compression resistance

- Transit vibration simulation

- Carton drop testing

- Seal integrity tests for food-contact packaging

These tests support e-commerce, fragile goods, electronics, and industrial shipments.

Importance of Physical and Mechanical Testing

Ensures Consumer Safety and Product Reliability

Testing identifies weaknesses in design, materials, or assembly before the product reaches the market. This reduces injury risks and supports safe use.

Supports Regulatory and Market Compliance

Global markets require mechanical and physical safety verification. Without accredited testing, products may be rejected at customs or removed from retail channels.

Reduces Recalls and Operational Risk

Testing helps detect non-conformities early in development and production. This reduces recall probability, shipment delays, and warranty claims.

Strengthens Brand Confidence

Consistent compliance and reliable performance support long-term customer trust and reduce reputational risk.

Common Applications Across Industries

Consumer Goods: Textiles, Toys, Furniture, and Packaging

Textiles are tested for tear strength, seam durability, and colorfastness. Toys undergo small parts and mechanical hazard tests to comply with child safety standards. Furniture is assessed for load-bearing capacity, stability, and structural integrity. Packaging materials undergo compression and transport simulations to ensure safe product delivery.

Electronics and Electrical Appliances

Electronic devices must withstand daily stress, from button operation to screen pressure. Drop tests, vibration tests, and mechanical endurance assessments verify long-term reliability. Physical and mechanical testing complements electrical safety standards such as IEC 60335 for household appliances.

Automotive Components and Industrial Parts

Automotive parts face extreme conditions, from road vibrations to high-impact collisions. Tensile, fatigue, and impact tests confirm that materials used in seats, airbags, and structural components meet international safety requirements. Industrial equipment undergoes similar evaluations to ensure reliability under heavy operational loads.

Food-Contact Packaging and Materials

Containers, films, and wraps used in the food industry must not only comply with chemical migration tests but also mechanical performance standards. Packaging integrity tests confirm that food remains safe, uncontaminated, and securely sealed during transport and storage.

Physical and mechanical testing standards are indispensable for ensuring product safety, regulatory compliance, and consumer confidence. Without structured testing programs, businesses risk recalls, penalties, and loss of market access.

To navigate these challenges, third-party testing providers such as ECQA play a critical role. Accredited laboratories offer unbiased evaluations of product performance and safety. By aligning testing programs with international benchmarks, ECQA ensures business can meet compliance requirements while safeguarding consumer trust.

Request Free Sample Report

Request Free Sample Report