Step-by-Step Guide to Production Inspection for Sourcing

Production inspections are your key to ensuring product quality at every stage of the sourcing journey. Ensuring product quality standards is a crucial aspect of any successful sourcing journey. It helps build trust with your customers, minimize risks, and avoid costly delays or rework.

From the initial selection of raw materials to the final pre-shipment inspection, each step plays a crucial role in ensuring product quality and reducing the risk of costly defects, returns, or even product recalls. This guide explores the critical quality steps involved, with a particular emphasis on the essential role of production inspections.

By understanding each step, you can create a robust quality control system. Furthermore, by using production inspection, companies have seen up to 20% reduction in defect rates, and 15% improved lead time.

Production Inspection Process for Your Sourcing Journey

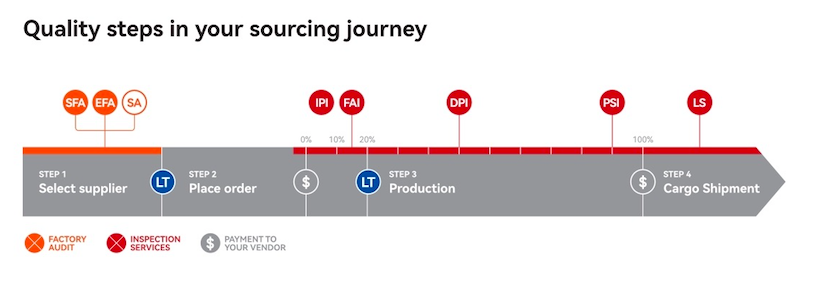

Step 1: Select Supplier

Social Factory Audit (SFA):

Evaluate a supplier’s social compliance practices within their factory environment, including labor rights, working conditions, and ethical sourcing. This audit often includes checks for fair wages, safe working conditions, and compliance with labor laws. For example, an SFA might verify that workers have access to protective equipment, and are not working excessive overtime.

Environmental Factory Audit (EFA)

Assess a supplier’s environmental practices within their factory, such as waste management, energy efficiency, and pollution control measures. This can include evaluating the use of renewable energy, proper disposal of waste materials, and if the supplier is following guidelines from organizations like the Environmental Protection Agency (EPA). A good EFA ensures the factory is working with a commitment to a greener future.

Supplier Audit (SA)

Conduct a comprehensive assessment of the supplier’s overall performance, including their track record, financial stability, and ability to meet quality and delivery requirements. A supplier audit may involve checking certifications, financial records, and past production performance. This audit helps reduce the risk of partnering with an unreliable supplier. A good SA will ensure the supplier is able to deliver what they promise.

Step 2: Place Order

- Lead Time (LT): Negotiate and confirm lead times with your supplier to ensure timely delivery of your order. Agreeing on a realistic lead time is vital, and also agreeing on regular updates to track the product.

Step 3: Production

First Article Inspection (FAI)

Inspect the first production run to ensure it meets all specifications and requirements before proceeding with mass production.This involves a full check of the first produced unit and helps identify any issues before mass production starts, avoiding costly mistakes later in the process. For example, a FAI would check all the parts of a new electronic product are correct, assembled right, and work perfectly.

Initial Production Inspection (IPI)

Inspect the first batch of products at the start of production to identify and address any quality issues early on. This is usually done when 10-20% of the production run is complete, to check for any issues early on. For example, during the production of t-shirts, an IPI may check the first few hundred are the correct material, size, and colour.

During Production Inspection (DPI)

Performed at various stages of production, DPI’s offer ongoing monitoring of the manufacturing process, enabling the early detection and rectification of any quality issues. This proactive approach prevents defects from multiplying and impacting the entire batch. For example, when producing leather bags, a DPI may check the stitching at various stages of production to ensure quality is consistent.

Pre-Shipment Inspection (PSI)

Inspect the finished goods before shipment ,ensuring the finished products meet all quality standards and are ready for delivery. This is your last line of defense before the products reach your customers. The PSI usually happens when at least 80% of the products have been produced and packaged, and the final check will focus on quantity, quality, and correct packaging. It is a last opportunity to fix any remaining issues before shipping.

Monitor production lead times to anticipate and address any potential delays.It is important to monitor the lead time to help plan the logistics and shipping process, so you can update the relevant parties if there are going to be delays. This ensures the supply chain has enough time to prepare.

Step 4: Cargo Shipment

Loading Supervision (LS)

Supervise the loading of your cargo to ensure proper handling and prevent damage during transit. A loading supervision will check to ensure the products are loaded into the correct containers, and are packed correctly to avoid any damages during transit. This can include proper packaging and correct loading.

Benefits of Production Inspections

With production inspection, you gain direct access and control over your manufacturing process, allowing you to:

- Proactively catch and rectify potential issues before they escalate into major problems, saving time and money.

- Verify that products adhere to specified quality standards and regulatory requirements, safeguarding your customers and your brand reputation

- Gain valuable insights into the production process to make informed decisions about supplier relationships and future orders.Research has shown that companies that focus on quality control, have a higher repeat purchase rate

Beyond the essential steps outlined above, partnering with a reliable quality assurance provider like ECQA can significantly enhance your sourcing journey. By investing in quality steps and production inspections, you are investing in the long-term success of your business and the satisfaction of your customers. Studies by ASQ, show that a focus on quality can lead to increased customer satisfaction and brand loyalty. Ready to elevate your sourcing journey with proactive quality assurance?

Request Free Sample Report

Request Free Sample Report