Acceptable Quality Limit (AQL): Complete Guide for Quality Control

Acceptable Quality Limit (AQL) is a statistical method used to decide how many defects are allowed in a production batch during quality inspection. It provides a measurable threshold that helps buyers and manufacturers evaluate whether a lot meets agreed quality standards. AQL allows both sides to manage quality expectations and inspection resources in a predictable manner.

AQL is based on sampling rather than examining every product. The method uses standard tables from ISO 2859 to determine how many units must be checked and how many defects are acceptable. This approach supports consistent decision making across different factories, products, and industries.

AQL is not a prediction of total defects in the entire batch. It is a risk-management tool that uses probability to evaluate quality with a limited but statistically valid number of samples. By using AQL, businesses can maintain consistent inspection practices even across large or varied production volumes.

Why AQL Matters in Quality Control

AQL provides a standard framework for assessing product quality without inspecting every item. It supports efficient inspection by using samples that represent the full batch. This helps reduce inspection time, cost, and operational overhead while still maintaining confidence in product quality.

The method is widely used because it aligns with international standards such as ISO 2859 and ANSI/ASQ Z1.4. Industries that manufacture consumer goods, electronics, apparel, industrial parts, toys, and medical devices rely on AQL to maintain consistent quality levels across different suppliers and regions.

AQL also helps reduce risks associated with defective products, customer complaints, and regulatory issues. By applying AQL consistently, companies can strengthen quality assurance across the supply chain.

How AQL Works

AQL works by selecting a small number of units from a larger batch and checking them for defects. The results are compared with predefined acceptance limits. If the defect count is within the limit, the batch passes. If the defect count exceeds the limit, the batch fails.

AQL standards define the sample size and the acceptable number of defects based on lot size, inspection level, and selected AQL values. These parameters determine how strict the inspection will be.

The process ensures a balanced approach between inspection effort and quality risk. Businesses select AQL levels based on product type, criticality, regulatory requirements, and historical supplier performance.

AQL Defect Classifications

Defects in AQL inspections are grouped into three categories. Each category has its own acceptance threshold.

Critical Defects

Critical defects are those that can cause safety hazards, regulatory violations, or product malfunction. These defects make the product unsuitable for use. AQL for critical defects is usually set to 0 because no safety-related failure is acceptable.

Examples include sharp edges in toys, contaminated food items, or electrical hazards in devices. Critical defects are treated with zero tolerance due to compliance and safety requirements.

Major Defects

Major defects reduce functionality or significantly affect usability. They do not pose safety risks but can cause customer dissatisfaction or returns. AQL values for major defects are often set between 1.0 and 2.5.

Examples include faulty zippers, broken components, or noticeable damage that affects product performance. These issues can affect brand reputation and product reliability.

Minor Defects

Minor defects are cosmetic or small issues that do not affect functionality. AQL values for minor defects are typically 4.0 or higher, depending on buyer requirements.

Examples include small paint variations, light scratches, or slight label misalignment. These defects may affect appearance but do not impact the intended use of the product.

Key Components of AQL

AQL inspections depend on several essential elements that determine how the sample is selected and evaluated.

Lot Size

Lot size refers to the total number of units produced under similar conditions. It determines the representative sample size based on ISO 2859 tables. Larger lots generally require larger samples for accurate evaluation.

Lot size helps ensure that sample selection reflects the diversity within the batch.

Sample Size

Sample size is the number of units selected for inspection. Sample sizes are predetermined by ISO 2859-1 based on lot size and chosen inspection level. The sample size affects inspection reliability and cost.

A larger sample reduces quality risk but increases inspection time. A smaller sample reduces cost but increases the chance of missing defects.

AQL Values

AQL values determine how many defects are allowed within the sample. Common levels include 0.65, 1.0, 1.5, 2.5, and 4.0.

The correct AQL value depends on product risk, customer expectations, and regulatory requirements. Different values can be applied to critical, major, and minor defects.

Inspection Levels

Inspection levels determine how many samples are taken relative to the lot size. ISO 2859 defines two categories:

General Inspection Levels

GI, GII, GIII

General levels are used for most inspections. GII is the default level and provides balanced inspection coverage.

Special Inspection Levels

S1, S2, S3, S4

Special levels reduce or increase sample size for specific checks, such as functional tests or destructive tests.

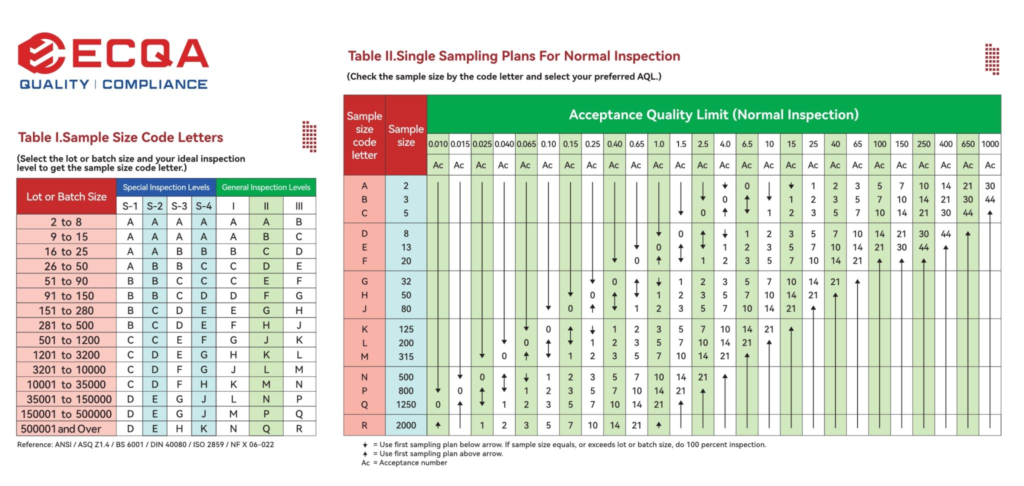

AQL Tables

AQL tables are used to determine the sample size code letter and acceptance thresholds. They provide a consistent reference for inspectors and quality teams. These tables come from standards such as ISO 2859-1.

The tables ensure consistency and reduce subjective judgment across different inspections.

Understanding AQL Sampling Tables

AQL tables contain two main parts:

- A table that converts lot size and inspection level into a sample size code letter

- A table that converts the code letter into the actual sample size and acceptance limits

To use the tables, inspectors identify the lot size, choose the inspection level, and then reference the tables to find the corresponding sample and permissible defect counts.

AQL tables ensure that inspections follow a standardized method supported by statistical probability.

How to Read an AQL Sampling Table

- Identify the Lot Size: Determine the total number of units in the batch to be inspected.

Example: A batch contains 5,000 units.

- Select the Inspection Level: Choose the appropriate inspection level based on the product type and quality requirements.

Example: General Inspection Level II.

- Determine the AQL Levels: Set the AQL thresholds for critical, major, and minor defects.

Example: Critical defects = 0%, Major defects = 1.5%, Minor defects = 4.0%.

- Consult the AQL Table: Find the row corresponding to the lot size and chosen inspection level. Identify the sample size code letter and its corresponding sample size.

Example: Lot size of 5,000 units with Level II gives code letter L, corresponding to a sample size of 200.

- Inspect the Sample: Examine the selected sample units and categorize any defects.

Example: Inspect 200 units and record 1 critical defect, 2 major defects, and 5 minor defects.

- Compare to AQL Thresholds: Refer to the AQL table to check the acceptance and rejection thresholds for the defects.

Example: AQL thresholds allow 0 critical defects, 7 major defects, and 10 minor defects.

- Make the Decision: Accept or reject the batch based on whether the defects fall within the acceptable range.

By mastering the AQL calculation process, businesses can improve their quality assurance practices and uphold high standards across all production batches. For quick calculation, you can use our AQL calculator.

Benefits of AQL for Quality Control

AQL supports stable quality management systems. It helps businesses optimize their inspection processes and maintain predictable quality outcomes.

Consistent Product Quality

AQL provides clear standards for acceptable variation. This consistency helps maintain product reliability across multiple batches.

Efficient Inspections

AQL sampling reduces inspection time and cost while maintaining statistically valid conclusions about quality.

Better Risk Management

AQL helps identify defective products before they reach customers. This reduces exposure to recalls, rework, and brand damage.

Improved Supplier Accountability

Clear AQL requirements help suppliers understand expectations. When both sides use the same criteria, communication improves and disputes decrease.

Supports Regulatory Alignment

AQL sampling aligns with international quality frameworks such as ISO 2859, strengthening overall compliance efforts.

Common Challenges in AQL Implementation

AQL is effective when applied correctly, but businesses may face certain operational challenges.

Sampling Errors

Incorrect sampling methods can reduce the reliability of inspection results. Proper training and standardized procedures are essential.

Ambiguous Defect Classification

Unclear criteria for defect categories can create disagreements between inspectors and suppliers. Detailed definitions and photo examples help avoid confusion.

Supplier Resistance

Suppliers may lack familiarity with AQL or may misunderstand inspection requirements. Clear communication and training can help reduce resistance.

Inconsistent Documentation

A lack of documentation reduces traceability and complicates quality tracking. Standardized forms and inspection logs help maintain long-term consistency.

The AQL system remains an indispensable tool in quality control, empowering businesses to deliver products that meet stringent standards and exceed customer expectations. By defining clear defect thresholds, adopting robust inspection methods, and leveraging advanced technologies, companies can streamline operations and achieve consistent excellence in product quality. Need help determining the right AQL level? Contact ECQA for expert guidance.

If you’re looking for a more in-depth guide on AQL, download our free AQL ebook today.

FAQs of Acceptable Quality Limit (AQL)

What is AQL?

AQL refers to the Acceptable Quality Limit, which defines the maximum number of defects permitted in a sample before a production lot is rejected. It is a standardized method used in quality control to maintain predictable and consistent inspection results.

How does AQL sampling work?

AQL sampling selects a specific number of units from a batch and evaluates them for defects. The sample size and defect limits are determined by ISO 2859 tables based on lot size, inspection level, and selected AQL values. The batch passes when the defects found fall within the allowed limits.

What are critical, major, and minor defects?

Critical defects are issues that create safety hazards or regulatory failures. Major defects affect functionality or usability and may cause customer complaints. Minor defects relate to appearance and do not impact the product’s intended use. Each category has its own AQL threshold.

How do I use an AQL table?

To use an AQL table, identify the lot size, choose the inspection level, and locate the sample size code letter. Then refer to the acceptance table to find the sample size and the maximum allowable defects for each defect category. These values determine the pass or fail result for the batch.

What are common AQL values?

Common AQL values include 0 for critical defects, 1.0 to 2.5 for major defects, and 4.0 to 6.5 for minor defects. Different industries adopt different thresholds depending on risk, regulations, and buyer requirements.

Request Free Sample Report

Request Free Sample Report