What Is Hardness Testing? Methods, Standards, and Applications

Hardness testing is a widely used material evaluation method that measures a material’s resistance to localized plastic deformation, typically caused by indentation, penetration, or impact. In industrial practice, hardness values are used as practical indicators of material condition, processing quality, and consistency across production batches.

Because hardness testing is efficient, repeatable, and applicable to a wide range of materials, it has become a standard tool in manufacturing quality control, inspection, supplier qualification, and failure investigation. Hardness requirements are commonly specified in engineering drawings, purchase specifications, and acceptance criteria across global supply chains.

Understanding What Hardness Represents

Hardness is not a fundamental physical constant. It reflects a combined response of several mechanical characteristics, including yield strength, elastic behavior, strain hardening capacity, and microstructural condition. For brittle materials, fracture resistance and crack initiation behavior also influence measured hardness.

As a result, hardness should be interpreted as a derived performance indicator. Its reliability depends on selecting an appropriate test method, controlling test conditions, and evaluating results against relevant standards and material context.

Why Hardness Testing Is Used in Industry

Hardness testing is commonly included as part of broader physical and mechanical testing programs to verify material condition, processing quality, and production consistency.

Hardness testing plays a practical role at multiple stages of the product lifecycle:

- Verification of raw material grade and supplier consistency

- Validation of heat treatment and surface processing

- In-process quality control and batch comparison

- Pre-shipment and third-party inspection

- Failure analysis and root cause investigation

While hardness testing does not replace tensile, fatigue, or fracture testing, it provides fast and meaningful insight into material behavior when used correctly.

Overview of Major Hardness Testing Methods

Different hardness testing methods exist to address variations in material type, thickness, geometry, and inspection environment. The most commonly used industrial methods include Brinell, Rockwell, Vickers, Knoop, and Leeb hardness testing.

Brinell Hardness Testing (HB / BHN)

Brinell hardness testing uses a hardened steel or tungsten carbide ball of defined diameter pressed into the test surface under a specified force. After a controlled dwell time, the indentation diameter is measured and used to calculate the hardness value.

This method produces a relatively large indentation, which provides good representativeness for materials with coarse grain structures or non-uniform composition.

Key characteristics

- Suitable for cast iron, forgings, and structural metals

- Effective for heterogeneous or coarse-grained materials

- Not suitable for thin parts, small components, or finished surfaces

Typical hardness range

HB 8–650

Common standards

ISO 6506

ASTM E10

GB/T 231.1

Rockwell Hardness Testing (HR)

Rockwell hardness testing determines hardness based on the depth of permanent indentation produced under a minor load followed by a major load. The test uses either a diamond cone or steel ball indenter, depending on the selected scale.

Hardness values are read directly from the testing machine, making Rockwell testing efficient and suitable for production environments.

Key characteristics

- Fast operation with direct reading

- Small indentation size

- Suitable for finished components and routine inspection

Common scales

- HRC for hardened and heat-treated steels

- HRB for softer metals such as copper alloys and annealed steels

- HRA for thin or hard surface layers

Typical hardness range

HRC 20–70

Common standards

ISO 6508

ASTM E18

GB/T 230.1

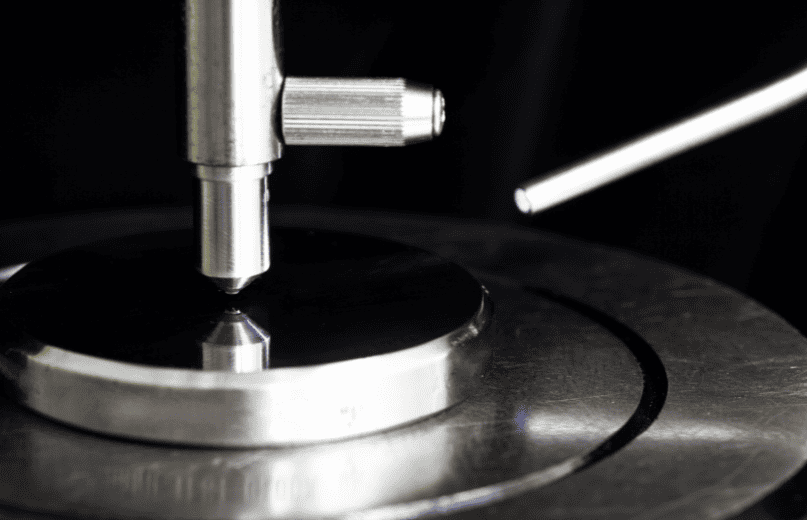

Vickers Hardness Testing (HV)

Vickers hardness testing uses a diamond pyramid indenter with a fixed geometry. Hardness is calculated from the applied load and the measured diagonal lengths of the indentation.

Because the same indenter geometry is used across all load levels, Vickers testing provides a continuous and consistent hardness scale.

Key characteristics

- High accuracy and repeatability

- Applicable to a wide hardness range

- Suitable for thin sections and small test areas

Load ranges

- Macro Vickers: ≥ 1 kgf

- Low-load Vickers: 0.2 to < 1 kgf

- Micro Vickers: 0.01 to < 0.2 kgf

Typical hardness range

HV 5–3000

Common standards

ISO 6507

ASTM E384

GB/T 4340.1

Knoop Hardness Testing (HK)

Knoop hardness testing is a micro-indentation method designed for very thin materials, brittle substances, and surface coatings. The elongated diamond indenter produces a shallow indentation with minimal penetration depth.

Hardness is calculated from the length of the long diagonal of the indentation, allowing evaluation of thin layers without significant substrate influence.

Key characteristics

- Very shallow indentation depth

- Suitable for coatings, ceramics, and glass

- High sensitivity to surface preparation and test conditions

Common standards

ISO 4545

ASTM E384

Leeb Hardness Testing (HL)

Leeb hardness testing is a dynamic rebound method commonly used for portable and on-site inspection. A standardized impact body strikes the test surface, and hardness is calculated from the ratio of rebound velocity to impact velocity.

This method is especially suitable for large, heavy, or installed components that cannot be tested in a laboratory setting.

Key characteristics

- Portable and suitable for field inspection

- Applicable to large or assembled components

- Results influenced by surface condition and component mass

- Requires regular calibration and verification

Common standards

ISO 16859

GB/T 17394

Applications of Hardness Testing in Quality Control

Hardness testing is applied at defined control points within quality management systems to verify material condition and process consistency. Typical applications include:

- Incoming material inspection to confirm material grade and supplier conformity

- Heat treatment verification to assess processing effectiveness

- In-process monitoring to detect process variation

- Pre-shipment inspection to support acceptance and delivery requirements

- Technical dispute resolution using objective material data

Deviations from specified hardness ranges often indicate upstream issues such as material substitution, improper heat treatment, or process instability.

Hardness Testing Services for Industrial Use

Professional hardness testing services provide standardized testing, calibrated equipment, and documented results aligned with international standards and customer specifications. Proper method selection and result interpretation are essential to ensure data reliability and practical relevance.

To request hardness testing support, contact our team with details of your material type, quantity, and testing requirements. We will recommend a suitable approach and provide a clear quotation based on your application.

Request Free Sample Report

Request Free Sample Report