Lighting Inspection

ECQA's Key Aspects of Lighting Inspection

1. Workmanship (visual inspection) – We visually inspect each lighting fixture for any defects or imperfections in manufacturing, such as scratches, dents, or blemishes. This includes checking the overall finish and ensuring it meets the required quality standards.

2. Product Specifications– We verify that the lighting matches the exact description, style, and color ordered, and that all labeling is correct, legible, and securely attached. This includes checking the materials used, dimensions, and any special features.

3. Dimensions and Weight– We confirm the lighting meets the specified size and weight requirements to ensure it fits the intended application and packaging.

4. Assembly/Installation Checks– Ensuring the components fit together correctly and the fixture can be installed properly, including checking mounting points, connections, and ease of assembly.

5. Full Function Test– Testing all functions of the lighting, including switching, dimming, and any special features like color changing or remote control operation. We verify that all functions operate smoothly and as intended.

6. Coating Adhesion Test– Evaluating the adhesion of any coatings or paint on the fixture using standardized tests like cross-hatch or pull-off tests. This ensures the coating is durable and resistant to flaking or peeling.

7. Colorfastness Check– Assessing the resistance of colored components to fading or discoloration caused by exposure to light or environmental factors. This ensures the product maintains its original color over time.

8. Stability Test– Evaluating the stability of the fixture to ensure it won’t easily tip over, especially for floor lamps or fixtures with a small base. This helps prevent accidents and ensures user safety.

9. High Voltage Test– Testing the insulation of the fixture to ensure it can withstand high voltages without electrical breakdown. This is crucial for preventing electrical shocks and ensuring safety.

10. Function/Current Check– Measuring the electrical current drawn by the fixture during operation to ensure it’s within the acceptable range. This helps prevent overloading circuits and ensures safety.

11. Power Cord Tensile Test– Testing the strength and durability of the power cord by applying tension to it. This ensures the cord can withstand pulling and bending without damage.

12. Internal Workmanship and Key Component Check– Inspecting the internal components and wiring for quality and proper connections. This includes checking soldering joints, wire terminals, and the overall construction of the fixture.

13. Aging Test– Testing the lifespan and performance of the fixture over an extended period by operating it for a specified number of hours. This helps evaluate its long-term reliability and durability.

14. Disassembly Test– Evaluating the ease of disassembly for maintenance or repair. This ensures that the fixture can be easily taken apart and reassembled if needed.

15. Light Distribution Analysis– We analyze how the light is distributed to ensure even illumination. This is important for creating a comfortable and visually appealing environment.

16. Electrical Safety Tests– We perform tests to ensure the fixture meets electrical safety standards, such as UL or CEstandards. This includes checking for proper insulation, grounding, and protection against electrical hazards.

17. Thermal Testing– We check for excessive heat buildup that could pose a safety hazard using thermal imaging cameras or temperature sensors. This ensures the fixture operates within safe temperature limits.

18. Mechanical Testing– We evaluate the mechanical strength and stability of the fixture to ensure it can withstand normal handling and use. This includes checking the strength of mounting points and the overall structural integrity of the fixture.

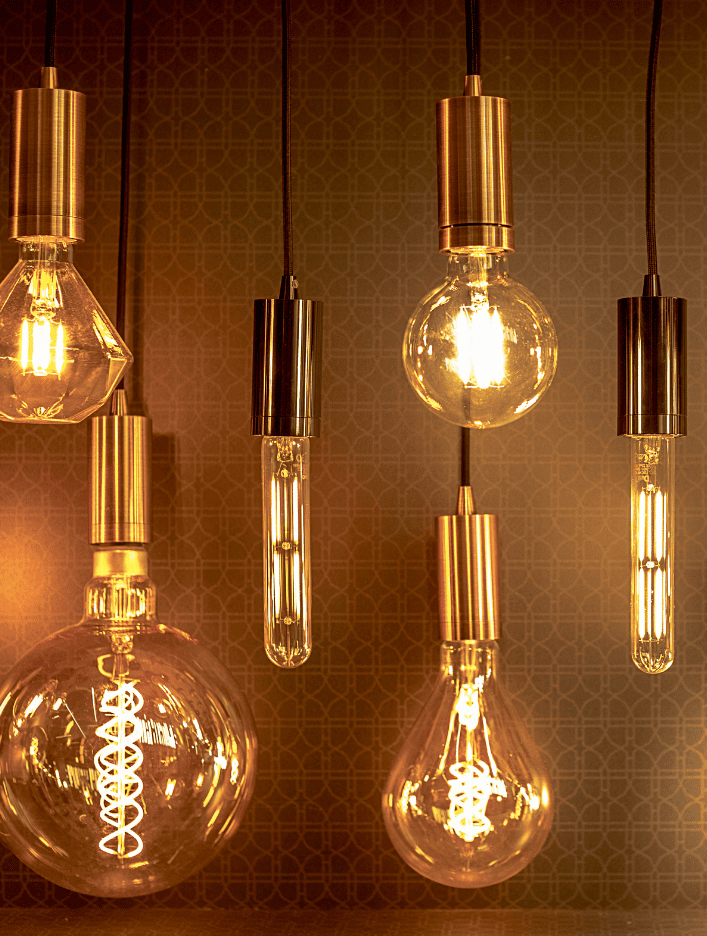

ECQA Lighting Inspection Services

ECQA offer inspection services for a complete range of lighting products, including:

Indoor Lighting: Wall lamps, wall lights, ceiling lamps, chandeliers, pendant lights, cabinet lights, closet lights, spotlights, track lights, projection lamps, sensor lights, bathroom lights, work lights, floor lamps, table lamps, daylight lamps, party lights, pillar lights, neon lights, energy-saving lamps, night lights, LED lights, halogen lamps.

Outdoor Lighting: Rock lights, solar decorative lights, solar lights, underwater lighting equipment.

Seasonal/Decorative Lighting: Luminous Christmas trees, Christmas tree lights, Christmas figurines, string lights, fairy lights, series lights.

Portable Lighting: Lanterns, flashlights, bicycle lights.

Light Bulbs: Light bulbs.

Detailed Lighting Inspection Reports

Lighting inspection is an essential process for any facility or infrastructure that relies on lighting systems. Whether it’s for commercial lighting, industrial lighting, or outdoor field lighting, a comprehensive inspection program helps ensure safety, performance, and energy efficiency.

After each inspection, ECQA provides a comprehensive lighting product testing and inspection report, summarizing the findings and highlighting any areas where the product did not meet the required standards. The report includes photos documenting the inspection process and any defects found.

This report serves as a vital tool for quality control, offering detailed information about the product’s compliance with industry standards and identifying areas for improvement. It ensures that the final product meets the expectations of both the manufacturer and the customer.

For a free sample report, please email us at sales@ecqa.com

- Free consultation

Lighting inspections play a vital role in ensuring the safety, performance, and longevity of lighting systems. By identifying and addressing potential issues early on, inspections help prevent accidents, optimize lighting quality, and reduce energy costs. Regular inspections also ensure that the lighting systems comply with relevant codes and standards, maintaining a safe and efficient environment.

Contact us today to learn more about how our expert inspection services can support your lighting production process and help you deliver top-quality products to your customers.

Request Free Sample Report

Request Free Sample Report